SLJ WCB Declutchable Gearbox Gear Operators

SLJ WCB Declutchable Gearbox Gear Operators

1. Installation suggestion:

1) Make sure the position of open or close on the gearbox is correspond to the valve’s position.

2) Avoid device failure due to lack of inspection of step one.

2. Adjustment process:

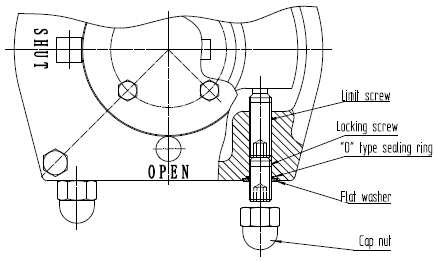

1) Please adjust the gearbox according to the position of valves, loosing gearbox corresponding limit screw, operating gearbox to make the valve on the correct position; then locked this limit screw. Operate the gearbox to turn the valve on another position, redone the above step and adjust the valve on the correct position,tight the cap nut.

(Pay attention to the use of "O" type sealing ring and flat washer)

2) Please pay attention to sequential adjust according to the position of valves.

3) After the adjustment is completed, operating the gearbox for full open / full closed to check the valve is on correct position.

Installation diagram of limit screw:

3. Maintenance

1) When gearbox is delivered, the gearbox has been adjusted on the correct position, when the user need to do some adjustment just operated according to the adjustment process.

2) When the gearbox is delivered, the gearbox has been filled with sufficient grease, the users do not need to add the grease any more.

3) If the gearbox is used in bad condition, check the state of the gearbox regularly. For example,if the fastener is loose or there is no oil leakage, Etc.

4) Warranty period: one year from the date of delivery. Duo to the quality problem, we will repair without any charges if during the warranty period, and only charge the material cost for repairing if more than the warranty period. By the buyer's damage caused by human factors, repair or materials provided by the supplier are at the cost price

5) If a product inventory stored for a long time, need to do a good job of surface protection, more important places are the flange connecting face and the valve shaft mounting hole, And check regularly.

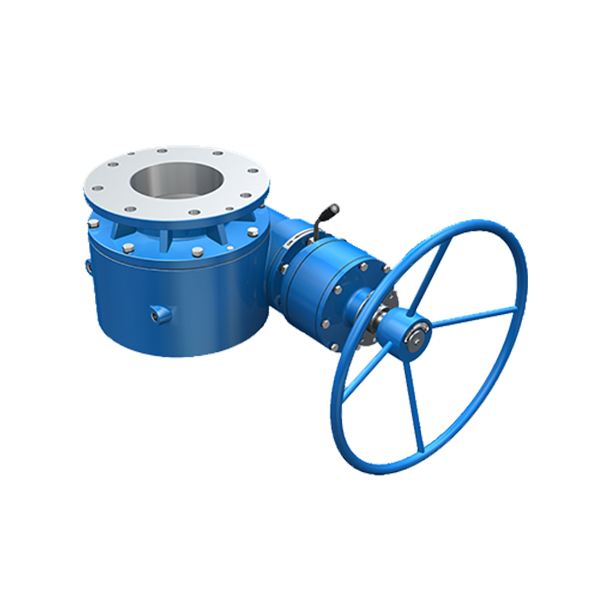

▪ Cast steel housing

▪ Full stamped hand-wheel (200-350)

▪ IP65 grade protection

▪ Nickel-plated input shaft, with more resistance to corrosion

▪ Ductile iron worm gear

▪ NBR sealing material

▪ Suitable for -20℃ ~ 120℃ working conditions

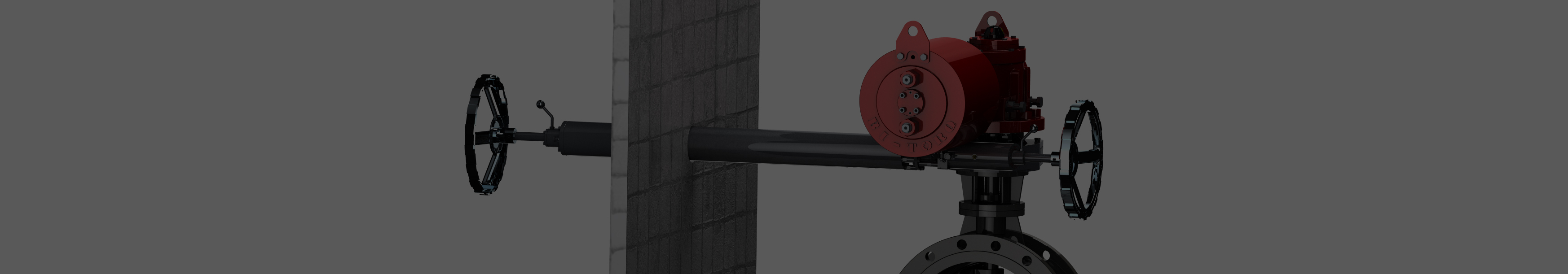

▪ Stainless steel or LCB casing

▪ IP68 grade protection

▪ Aluminum-bronze worm gear

▪ Stainless steel input shaft

▪ For high temperature up to 320℃

▪ For low temperature down to -40℃

▪ For marine use

Main Components List

|

Part name |

Material |

|

Small cap |

WCB |

|

Housing |

WCB |

|

Worm gear |

QT500-7/ Bronze |

|

Bracket cap |

WCB |

|

Hand wheel |

Carbon structural steel |

Main Technical Parameter

| Model | ratio | Rating input(Nm) | Rating output(Nm) | Efficiency(%) | Hand-wheel |

| SLJ26 | 26:1 | 50 | 300 | 23 | Φ200 |

| SLJ38 | 38:1 | 65 | 550 | 23 | Φ200 |

| 70 | 620 | Φ250 | |||

| 80 | 700 | Φ300 | |||

| SLJ54 | 54:1 | 75 | 1000 | 25 | Φ250 |

| 90 | 1200 | Φ300 | |||

| SLJ80 | 80:1 | 95 | 2000 | 26 | Φ350 |

| SLJ78 | 78:1 | 160 | 3200 | 26 | Φ600 |

| SLJ270 | 270:1 | 90 | 6000 | 25 | Φ500 |

| SLJ320 | 320:1 | 100 | 8000 | 25 | Φ500 |

| SLJ520 | 520:1 | 160 | 22000 | 25 | Φ700 |