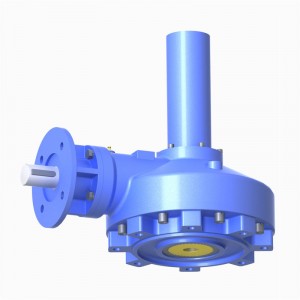

SB Bevel Electric Gear Operator Gearbox

SB Bevel Electric Gear Operator Gearbox

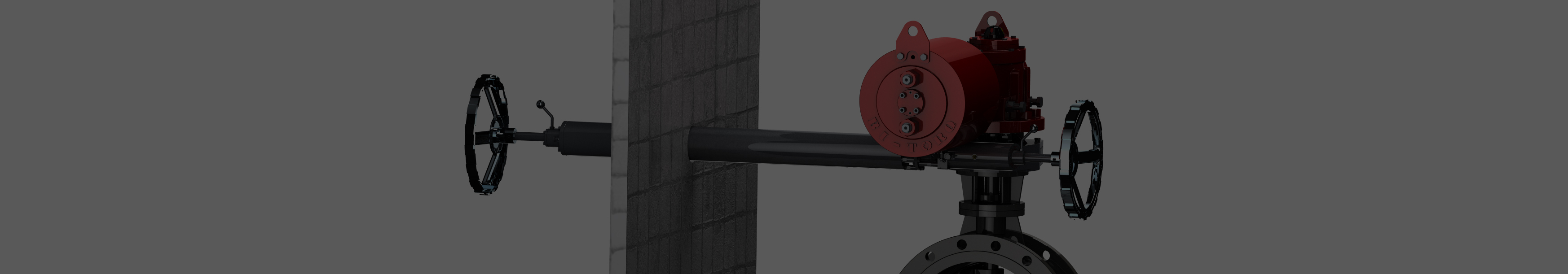

The flange of the input end of the gearbox is connected to the electric actuator, the input shaft is connected to the hole of the electric actuator, and the flange bolt is installed and tightened.

Connect the bottom flange of the gear operator to the upper flange of the valve and slide the valve shaft into the drive nut. Tighten the flange bolt. The valve can be closed by turning the hand-wheel clockwise and opened by turning the hand-wheel counterclockwise.

▪ WCB casing

▪ Welded hand-wheel

▪ IP67 grade protection

▪ Bronze nut

▪ NBR sealing materials

▪ Suitable for -20℃ ~ 120℃ working conditions

▪ IP68 grade protection

▪ Aluminum-bronze worm gear

▪ Stainless steel input shaft

▪ Designed with a lock mechanism

| Model | Gear ratio | Input flange | Input shaft | Input torque | Output flange | Max. valve stem(TW) | Rated thrust(N) | Output torque | Mechanical advantage |

| (Nm) | (Nm) | ||||||||

| SBS10 | 2.3:1 | F10 | 28 | 106 | F10 | 25 | 69200 | 220 | 2.1 |

| SBS20 | 2.35:1 | F10 | 28 | 172 | F12 | 32 | 108000 | 365 | 2.1 |

| SB-0 | 2.6:1 | F10 | 28 | 252 | F14 | 40 | 115000 | 590 | 2.4 |

| SB-1 | 3.6:1 | F10 | 28 | 290 | F16 | 45 | 120000 | 930 | 3.2 |

| SB-2 | 4:01 | F12/F14 | 38 | 414 | F20 | 48 | 220000 | 1490 | 3.6 |

| SB-3 | 4.1:1 | F12/F14 | 38 | 542 | F25 | 65 | 255000 | 2000 | 3.7 |

| SB-4 | 5.2:1 | F12/F16 | 38 | 723 | F30 | 70 | 265000 | 3400 | 4.7 |

| SB-5 | 6.3:1 | F16 | 38 | 810 | F35 | 105 | 452000 | 4600 | 5.7 |

| SB-6 | 7.11:1 | F16 | 45 | 970 | F40 | 120 | 820000 | 6200 | 6.4 |

1. Spline connection is used to connect the driving part with the bevel gear

2. Customers can process the reserved whole position according to their own actual working conditions

3. If you have any other requirements, please consult with the sales department of Stard-Gear

1) When the gearbox leaves the factory, the protection grade is IP65 and IP67.But only refers to the inside of the gearbox. IP protection level according to EN60529/IEC529 according to GB/T4208.IP65/IP67 applies to standard environment; IP68 is suitable for the water depth is not more than 1 meter, duration is not more than 72 hours of work environment. The working environment requirements need to be clarified in the previous contract.

2) gear box standard working environment temperature -20℃ ~ 120℃ seals are made of butadiene rubber (NBR) or liquid sealant gear box. When working in high temperature and low temperature environment, the seals are made of high and low temperature resistant seals according to the requirements of working conditions.(Special environment, need to be clear in the earlier contract)

3) The cover and other parts of the gearbox shall not be removed after delivery to the end customer, as doing so will damage the sealing of the gearbox and lead to leakage.