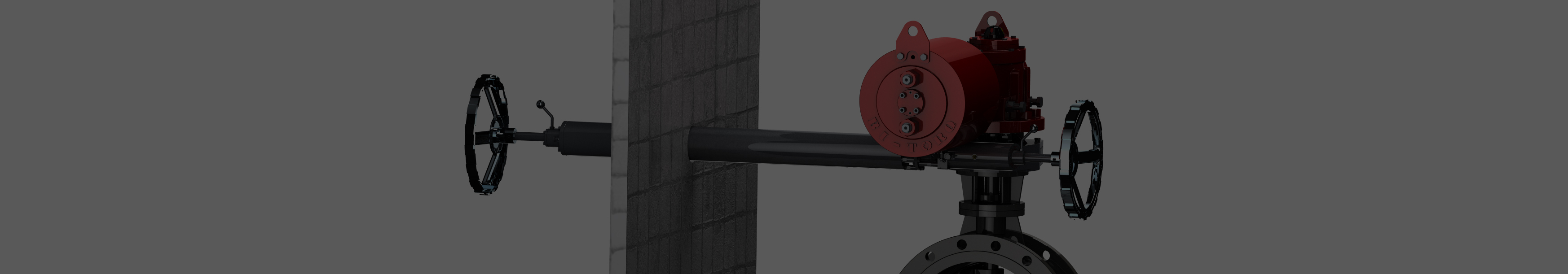

Ductile Iron Declutch Gearbox

Ductile Iron Declutch Gearbox

Connect the bottom side of the reducer to the valve and the bracket face to the cylinder. Then slide the valve shaft into the inner hole on the cylinder until the valve shaft end is well matched with the square hole of the cylinder on all four sides.

A tooth collision may occur when rotating the lever (by 180° outwards) to engage the worm. In such case, you need to turn the hand-wheel to a certain angle so that they can become engaged with each other.Actuating the device through pneumatic and manual means simultaneously is not allowed.

1. In the normal operating mode, the gear operator is “declutched” or disengaged from the actuator and valve drive train, allowing the actuator to freely move the valve without interference.

2. The automated control system or electric motor drives the actuator, and the declutch gear remains in a disengaged state.

1. When manual operation is necessary, such as during power outages or system maintenance, the actuator must first be disconnected from the power source to prevent unwanted accidental operation.

2. Next, the operator engages the clutch mechanism. This engagement allows the gear override to engage the actuator and valve drive train and operate the valve open or closed.

1. After manual operation is complete, the operator disengages the clutch mechanism to disconnect from the actuator and valve drive train.

2. After disengagement, the actuator can be reconnected to the power source for normal automated function.

▪ Standard Top Insert

▪ Body material: Ductile iron

▪ Full stamped hand-wheel (200-350)

▪ IP65 grade protection

▪ Nickel-plated input shaft, with more resistance to corrosion

▪ Ductile iron worm gear

▪ NBR sealing material

▪ Suitable for -20℃ ~ 120℃ working conditions

▪ IP67 grade protection

▪ Aluminum-bronze worm gear

▪ Stainless steel input shaft

▪ For high temperature up to 320℃

▪ For low temperature down to -40℃

▪ For marine use

Main Components List

|

Part name |

Material |

|

Insert |

Carbon steel |

|

Housing |

Ductile iron |

|

Worm gear |

QT500-7/ Bronze |

|

Bracket cap |

Ductile iron |

|

Hand wheel |

Carbon structural steel |

Main Technical Parameter

| Model | ratio | Rating input(Nm) | Rating output(Nm) | Efficiency(%) |

| SLJ30 | 35:1 | 35 | 300 | 24 |

| SLJ70 | 38:1 | 70 | 700 | 26 |

| SLJ120 | 54:1 | 90 | 1200 | 25 |